How to face time constraints

Problem solving and cost efficiency for densely urbanized contexts

www.snam.itOur integrated and flexible approach allows us to find optimal solutions when we face major challenges.

We know how to operate in the most difficult contexts

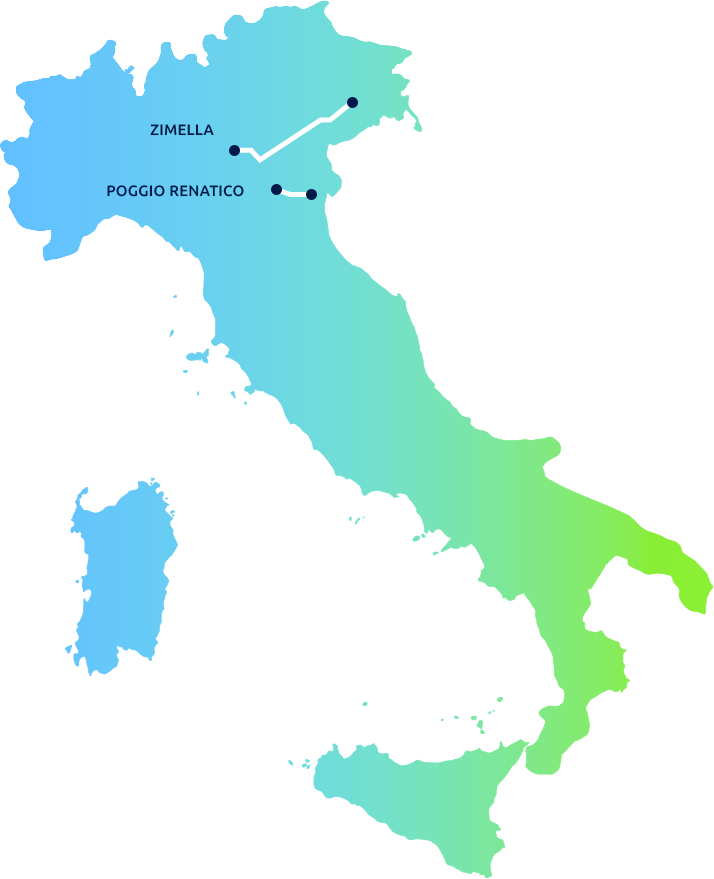

The Po Valley is one the most densely populated area in Europe. The new stretches of the network pipeline Poggio Renatico-Cremona stood out for their complexity. The simultaneous construction of 11 microtunnels faced us with a significant challenge. When increasing pressure on construction time created a gap in the contractors’ available machinery, we worked with them to develop an alternative solution.

150 km

Pipeline

2 million

Working hours

39

Municipalities crossed

2

Region crossed

The context: the EXPORT development project

Construction in the Po Valley of a new pipeline aimed at increasing the transport capacity in the northern part of the country thus allowing reverse flow gas supply, which is the physical export of gas from Italy towards Northern Europe.

The project included the realization of 450km of new 48’’ and 56’’ diameters pipelines, together with the construction of 2 new compressor stations empowered up to 85MW.

These infrastructural developments are also supporting the best resilience of the gas network to the increased volatility of flows, ensuring the security and diversification of supplies for all consumers.

A shift in technology, from microtunneling to Horizontal Directional Drilling, allowed us to diversify and involve a higher number of suppliers. The adoption of this new solution implied significant cost savings and a successful completion within the allotted time frame.

Horizontal Directional Drilling

Horizontal Directional Drilling (HDD) is a method of installing underground pipelines, cables and service conduit through trenchless methods. It involves the use of a directional drilling machine, and associated attachments, to accurately drill along the chosen bore path and back ream the required pipe. After the drill of a pilot hole and the following enlargement carried out by a back reamer, the pipeline is directly launched into the drill. Key elements to prevent collapse of internal walls of the hole are the mix of benthonitic fluids and the fluid pressure control.

Simple solutions for densely urbanized areas